AU: 1300 502 677 |

NZ: 0800 502 677

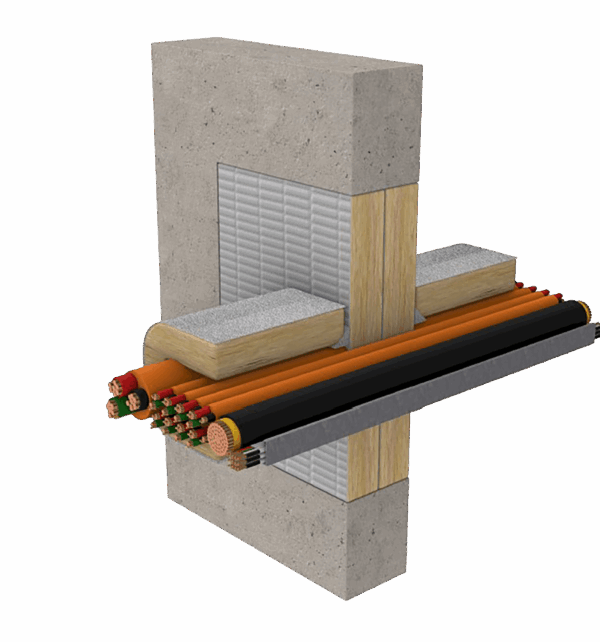

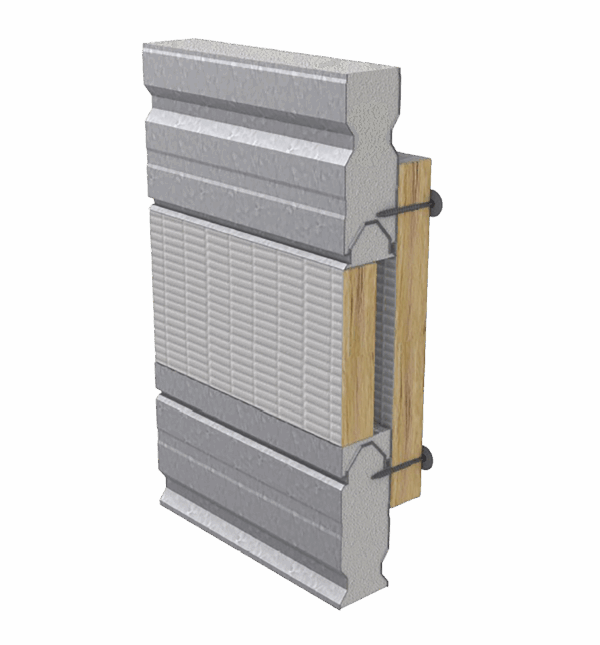

Ablative Coating is designed for sealing cut edges of BOSS Batts™ that treat large openings and service penetrations in fire rated walls, floors and ceilings. Once applied, it forms a durable fire-resistant barrier that prevents the passage of fire, smoke and hot gases between fire-rated compartments. The coating provides up to 4 hours fire resistance in blank openings and around metallic pipes, cable bundles, cable trays, HVAC ductwork and dampers. It is fully tested and approved to AS1530.4:2014 and AS4072.1-2005, ensuring compliant performance across a wide range of passive fire protection applications.

This water-based acrylic coating offers excellent fire-resistant and elastomeric properties while remaining flexible under normal temperatures to accommodate thermal and mechanical movement. It is low-VOC, halogen-free, fibre-free and asbestos-free, and is unaffected by oil, fungus, moisture and vermin, making it suitable for long-term internal use. The product delivers a clean, reliable finish and is safe and easy to apply using a brush or troweling equipment.

Ablative Coating™ has been fully tested in accordance with AS1530.4:2014 and AS4072.1:2005, achieving fire resistance levels up to FRL -/240/180 when used with BOSS Batts in approved wall and floor systems including concrete, masonry, plasterboard partitions, permanent polymer formwork, Speedpanel & Korok. The coating is also tested for acoustic performance up to 63 dB and air permeability to 600 Pa, ensuring compliance across a wide range of passive fire protection applications. Manufactured under ISO EN9001 quality standards, Ablative Coating contributes to Green Building sustainability criteria with low VOCs, halogen-free composition and long-term durability. For full system configurations, refer to the BOSS Fire System Matrix and associated test reports available at bossfire.com/resources.